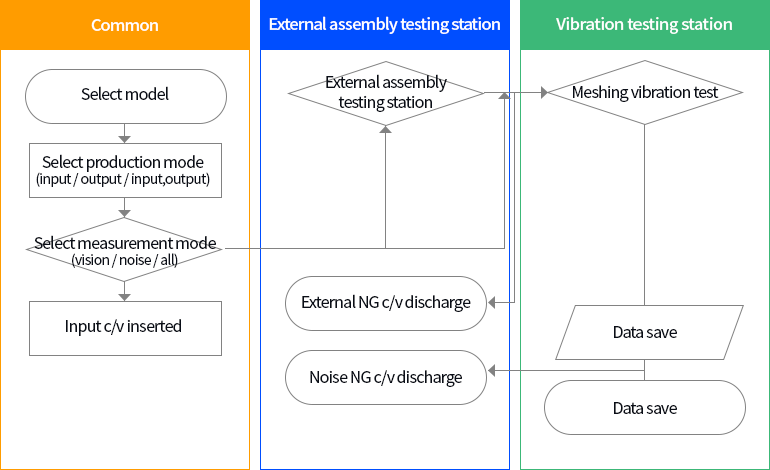

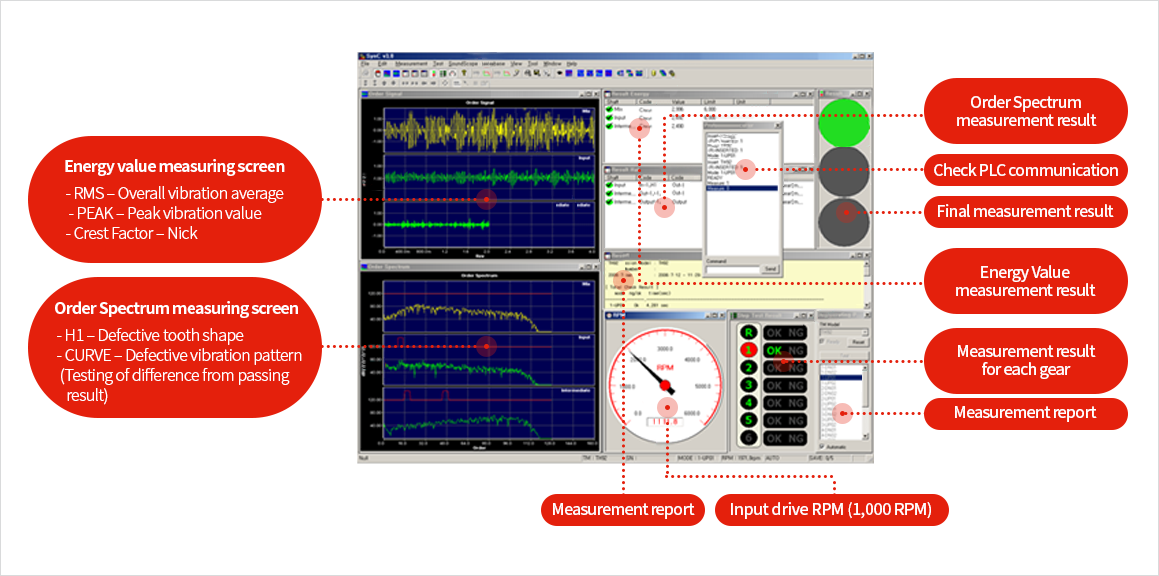

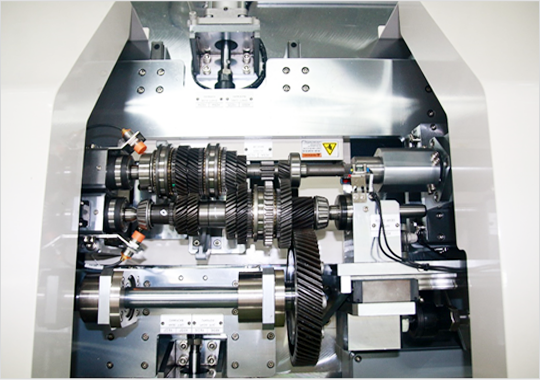

The gear shaft assembly is a core assembly component of a manual transmission, to which the gears transmitting power to the gear shaft and the shaft gear for gear changes are assembled, along with numerous other transmission components. The Gear Shaft Noise Tester measures and analyzes the vibration signals from the intermeshed gear teeth (Gear Mesh Frequency Structure-borne Noise) when gear changes are performed using the assembly to which gears, bearings and other components are assembled. This way, the machining quality of the gear tooth surfaces and the quality of assembly of the gear shaft assembly are tested.

The gear shaft vibration tester is equipped with automated measuring abilities, allowing for testing of machining and assembly quality of a finished transmission prior to final assembly.

Expected benefits

-

Improved production quality by testing gear shaft assembly prior to assembly into finished transmission product, preventing defects in gear machining and assembly of components

-

Prevention of damage to or breakage of internal transmission components by ensuring wrong components are not assembled into the transmission and subjected to high loads

-

Testing is carried out with actual gear changes using a full gear shaft assembly; assembly and machining quality of gear change-related components can be tested beforehand

-

Deburring of components prior to final assembly

-

Complete quality testing solutions lineup for improved transmission quality : gear-only testing, gear shaft assembly testing and finished transmission testing (EOL) solutions

-

-

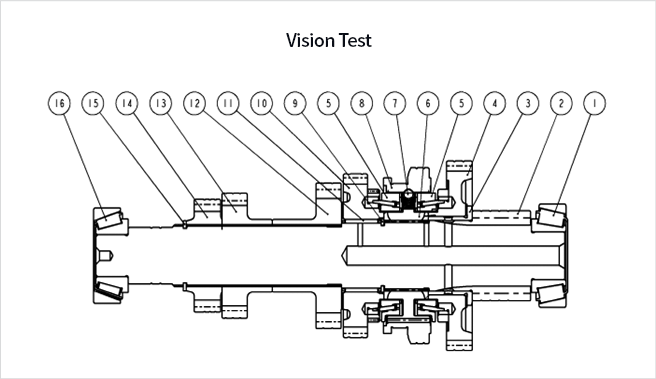

Full Machine (Noise & Vision Test)

-

Vision Station

-

-

-

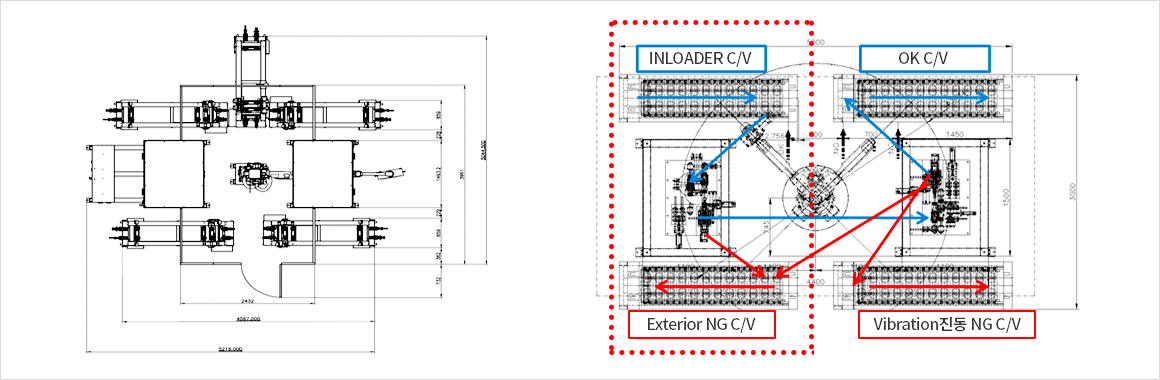

Standard Machine Dimension

-

-

-

Test Scopes

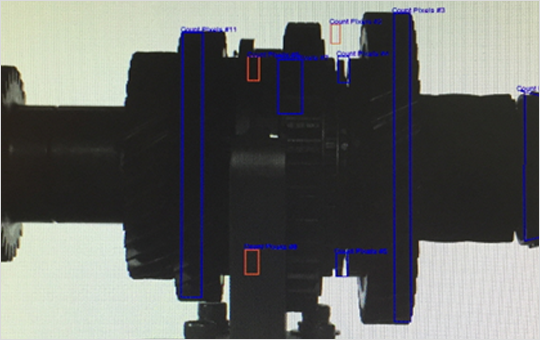

Bearing Assembly (Size)

Bearing Assembly (Size)1. Sync’ Ring Assembly (Assembled or not assembled)

2. Needle Bearing Assembly (Assembled or not assembled)

3. Snap Ring Assembly (Assembled or not assembled)

4. Bearing Assembly (Reverse assembly)

5. Gear Assembly Direction (Reverse assembly)

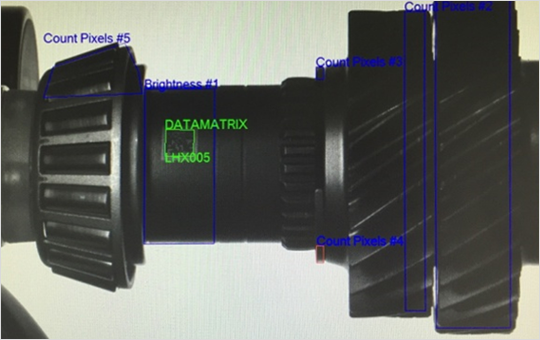

[Product Serial Number – Barcode reading rotating the shaft]

-

-

-

Product Serial Number- Barcode reading rotating the shaft

-

Assembly Test

-