System that automatically measures gear dimension quality

-

Prevents production

of large number

of defective product,

and contamination

of measurement results -

Improves production

efficiency through

stringent quality

testing -

Improves convenience

by automating periodic

self-inspections,

and eliminates human error

from self-inspections -

Saves time

by automating manually

performed

self-inspections.

Ⅰ. Scope of Supply

| Automatic Gear OBD/Runout Measurement System | Automatic Gear OBD/Runout Test Station | |

|---|---|---|

|

|

| Automatic Gear OBD/Runout Measurement System |

|---|

|

| Automatic Gear OBD/Runout Test Station |

|

Ⅱ. Specification

| Machine Components | ||

|---|---|---|

| Test Station Machine | Test Station |

|

| Display |

|

|

| Sensors | LVDT (High Accurate LVDT Displacement Measurement Sensor) |

|

| Fiber Sensor |

|

|

| Machine Components | |

|---|---|

| Test Station Machine | |

| Test Station |

|

| Display |

|

| Sensors | |

| LVDT (High Accurate LVDT Displacement Measurement Sensor) |

|

| Fiber Sensor |

|

| Controller | |

|---|---|

| PLC Controller |

|

| PC Controller |

|

| Controller | |

|---|---|

| PLC Controller |

|

| PC Controller |

|

| Measurement | |

|---|---|

| Repetitions |

|

| Measuring Speed |

|

| Measuring mode |

|

| 기어 고정방식 |

|

| 기어 Size |

|

| Resolution : 0.5μm or 1μm | |

| Manual Work Gear Loading/Unloading | |

| Spindle Runout Compensation | |

| Calibration using the Master Gear | |

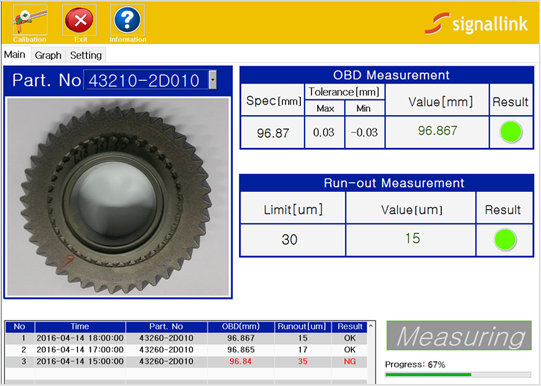

| Main, Graph, Setting, etc. GUI Windows Charts |

|

| Angle compensation algorithm for rotating portion step motor | |

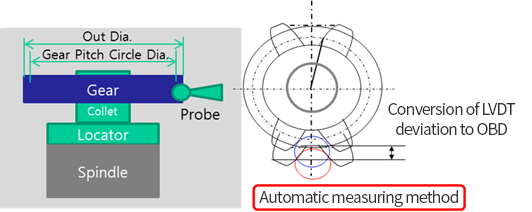

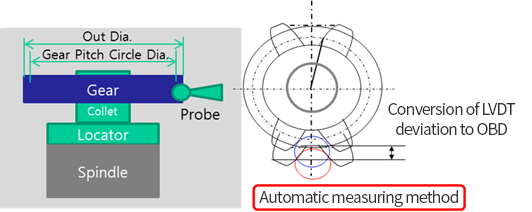

| Measuring method |

|

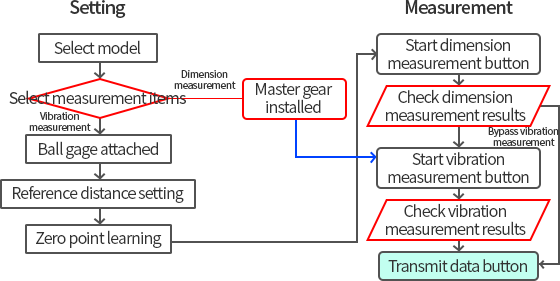

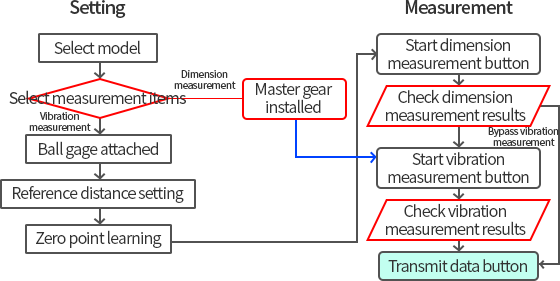

| Operation flow chart |  |

| Measurement | |

|---|---|

| Repetitions |

|

| Measuring Speed |

|

| Measuring mode |

|

| Gear securing method |

|

| 기어 Size |

|

| Resolution : 0.5μm or 1μm | |

| Manual Work Gear Loading/Unloading | |

| Spindle Runout Compensation | |

| Calibration using the Master Gear | |

| Main, Graph, Setting, etc. GUI Windows Charts |

|

| Angle compensation algorithm for rotating portion step motor | |

Measuring method

|

|

Operation flow chart  |

|